Video Covers when to use Certified and Compliant Tier 4f Generators. It's important to understand your application as there can be many disadvantages in using a Certified Generator for a Compliant application and vice versa.

Introduction to the EPA's Criteria Pollutants and how they evaluate the use of Emissions Control Technology like Selective Catalytic Reduction. Specifically addresses applications using reciprocating diesel and natural gas generators.

Brief overview of how the US EPA regulates the Air Permitting Authorities for power generation. Also introduces the concept of Title V and how Selective Catalytic Reduction(SCR) can often be used to avoid a Title V Permit.

Video provides a brief overview behind the US National Ambient Air Quality Standards (NAAQS) and how they apply to power generation equipment. This video introduces the concepts of Criteria Pollutants and Title V Permits as they relate to installations considering reciprocating engines/generators. It also provides the NOx evaluation levels the EPA uses to determine if a site is a major source.

This video covers how to calculate your EPA Potential to Emit (PTE). A specific example for a prime power reciprocating generator is covered. This same methodology can be used for other combustion equipment including emergency generators.

Video looks at implications of a Title V Permit for sites with reciprocating generators / engines. Concepts of Best Available Control Technology (BACT) and Continuous Emissions Monitoring System (CEMS) are introduced. Video explains why Selective Catalytic Reduction (SCR) is often desirable as it can be used to minimize implications of Title V

Selective Catalytic Reduction (SCR) technology is often used to reduce the stack height of a building, improving the overall architectural appearance. This technology reduces the source emissions for a generator greatly assisting the atmospheric dispersion modelling.

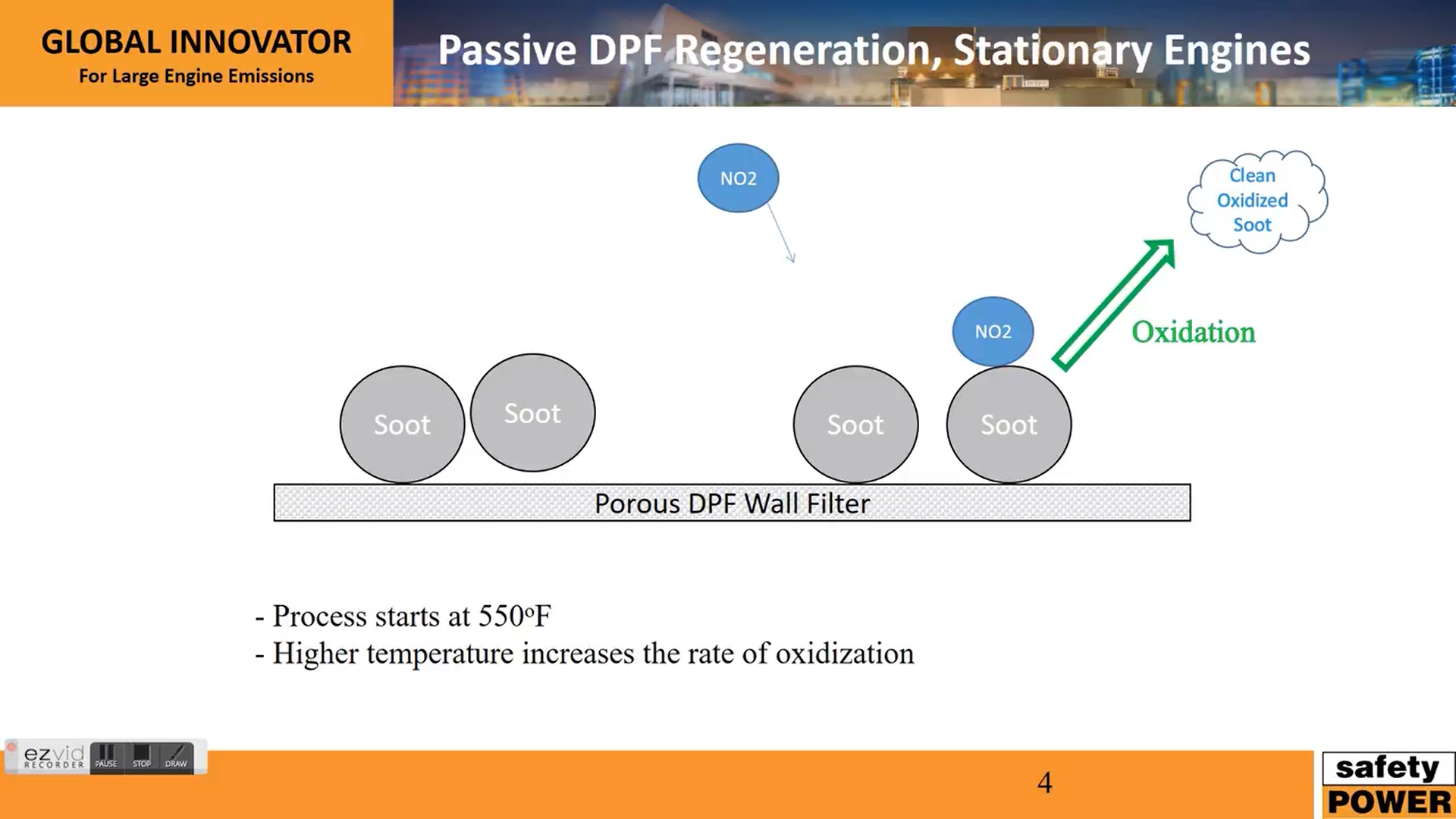

Diesel fired internal combustion engines release harmful particulate matter (PM) as an exhaust by-product. Ultrafine particles (UFP) consist of PM that is below 100nm in size. While larger particulate matter accounts for the majority of the mass in the exhaust, UFPs account for most of the particle number. It is important to consider the impact of UFPs in addition to the larger PM. UFPs have greater a deposition rate into lung tissue and are associated with severe health problems (including heart & lung disease). In this webinar, we explain how passive Diesel Particulate Filters (DPF) are the best commercially available method for reducing UFP emissions.

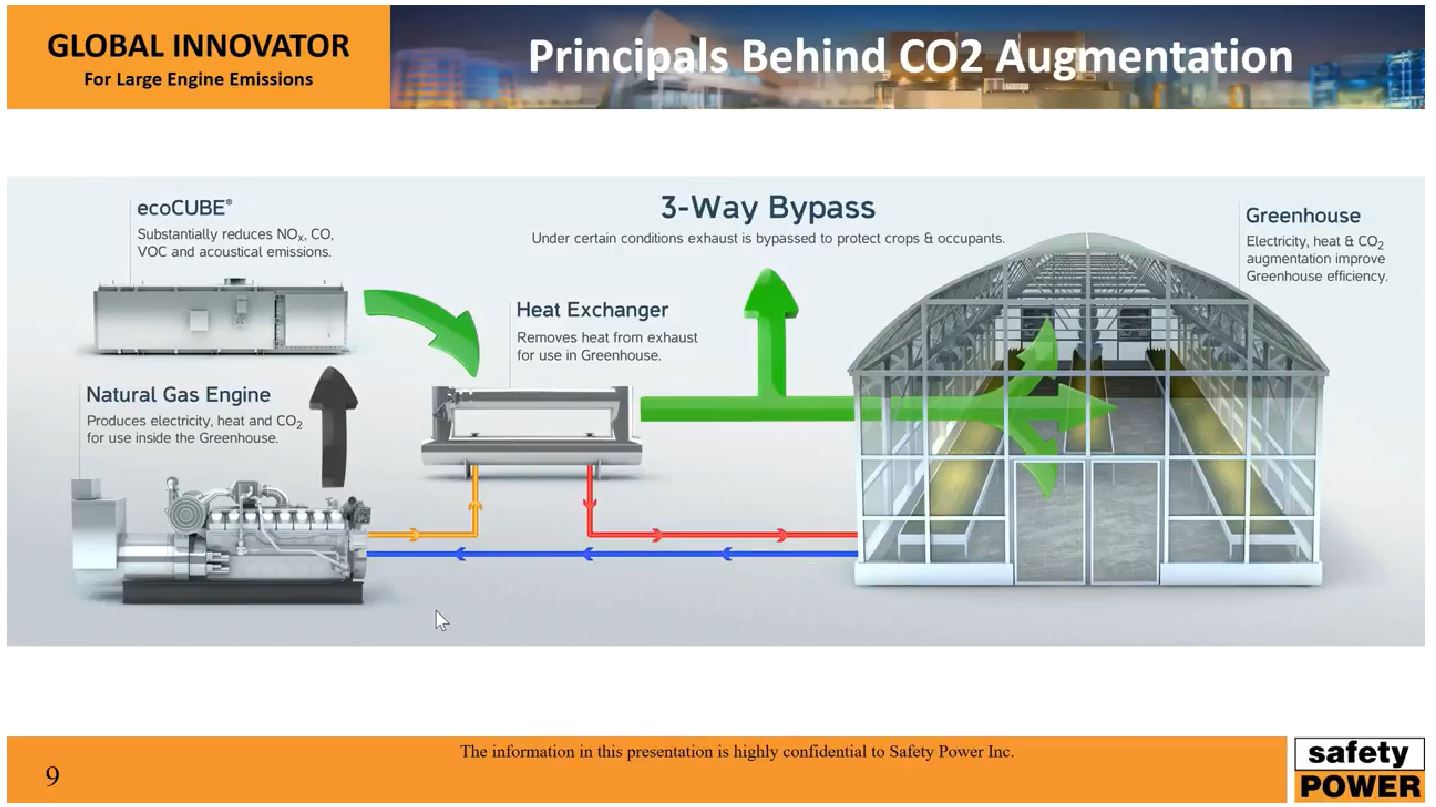

Lean burn natural gas engines combined with Selective Catalytic Reduction (SCR) technology is an efficient way to produce electricity, useful heat and CO2 for plants used in greenhouse applications. Learn more about the details of this process in this Webinar.

A brief review of NYSDEC's new ruling - 6 NYCRR Part 222. This video looks at what Economic Dispatch sources are, the advantages of participating in demand response programs, the emission limits set forth by the NYSDEC and some important deadlines.

Brief video that provides an overview of DPF regeneration process. Discusses the advantages of passive vs. active regeneration for stationary diesel engine applications.

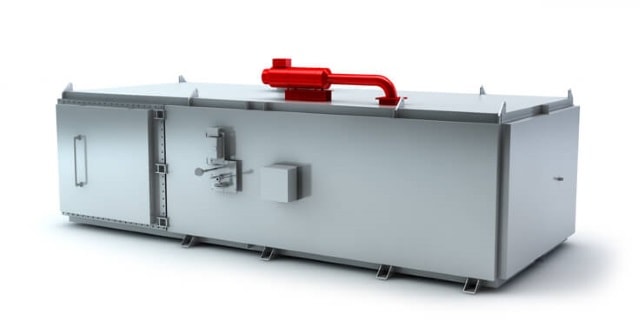

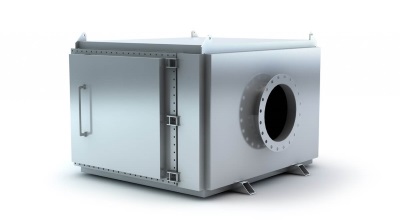

This video shows how the ecoCUBE is made and it shows a completed ecoCUBE being installed in a downtown data center in a major North American city.

Video highlighting our SCR installation at the Birchmount Energy Centre. This video shows one of our compact vertical SCR’s delivering <5 PPM of NOx output on a 3 MW Natural Gas Generator.

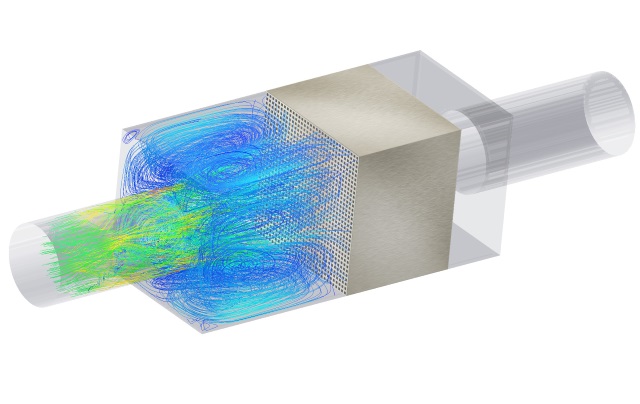

Safety Power goes through how Selective Catalytic Technology (SCR), Diesel Oxidation Catalyst (DOC) and Diesel Particulate Filters (DPF) work to reduce NOx, Particulate Matter (PM), CO and Hydrocarbons for Diesel Emergency and Prime Power Generators

Shows how the internal diverter valve works to reduce system back pressure when excessive cold starts have been performed.

The Webinar Covers:

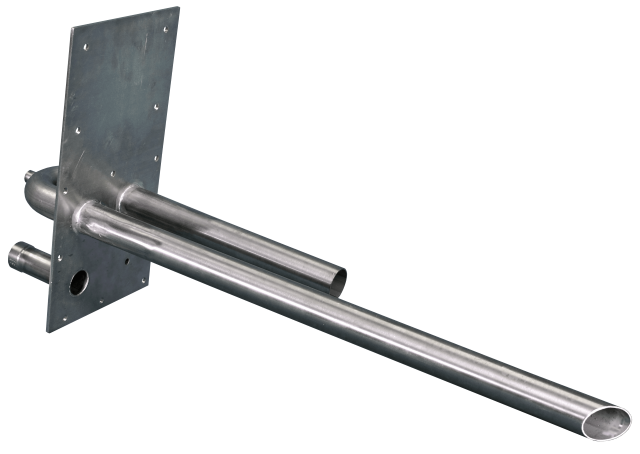

-Standard SCR Exhaust Designs (silencer positioning, expansion joints and relief devices).

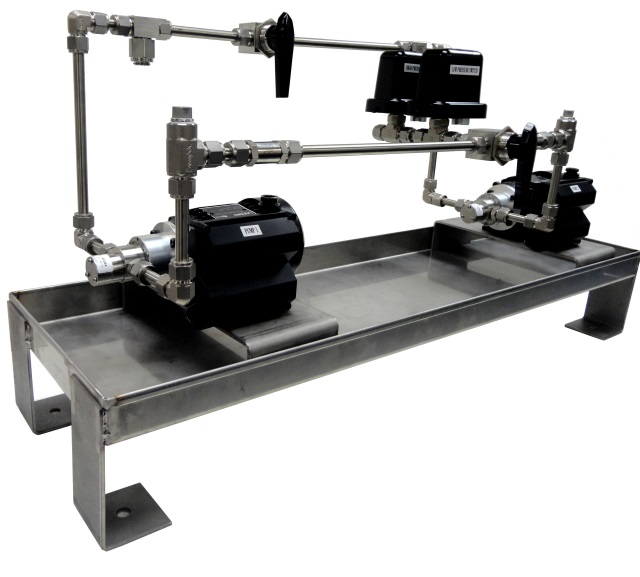

-Urea Tanks, Transfer Systems and Recommended Piping Designs.

-Control Wiring and Required Electrical Connections.

-Recommended SCR Placement for both Enclosure & Indoor Installations.

-Do's and Dont's for effective SCR Ancillary System Designs.

Shows how to integrate/install Safety Power's system into an engine enclosure. This video is meant to be an overall guide; please refer to our shop drawing package for specific details.